High Precision, Stunning flavours

The SAMS 15.01 Pharmaceutical-grade cutting mill enables manufacturers to standardize and scale their flower throughput to meet the ever-evolving production demands of the industry.

Meticulously crafted to preserve and maintain the flowers highest terpene and trichome levels.

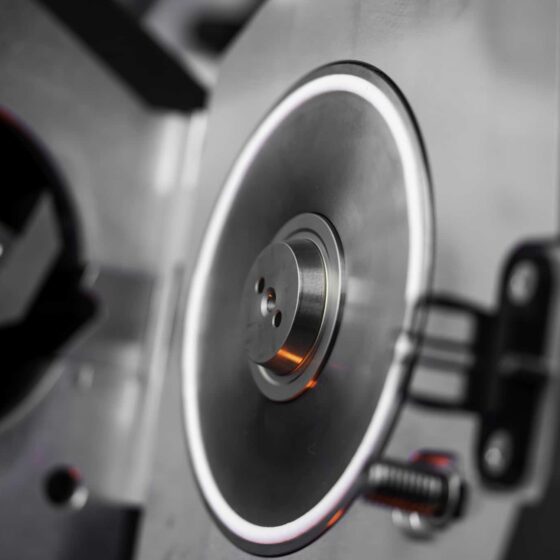

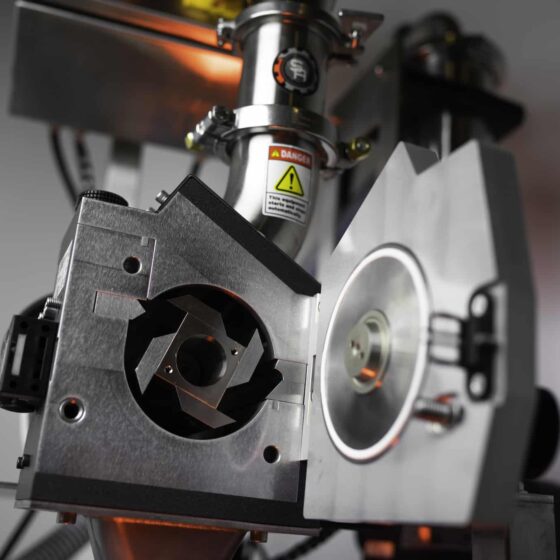

Introducing the SAMS.15 Semi-Automated Cutting Mill by Sample Automation. The newest product in our suite of cannabis equipment solutions, this Pharmaceutical-grade cutting mill enables manufacturers to standardize and scale their flower throughput to meet the ever-evolving production demands of the industry. The traditional weed-whacker style grinder limits operators output and quality by creating unwanted friction and heat and in turn, dramatically degrading the terpenes and trichomes of the flower. Sample Automation incorporates a negative pressure vacuum paired with a cyclone separator to create “no heat” technology. This was meticulously crafted to preserve and maintain the flowers highest terpene and trichome levels, which are essential to the quality and flavor profile of the end-product. The SAMS.15 Miller, allows manufacturers to customize your output material based on three variable elements: the grinding screen size, blade width and rotor blade speed.

Made in the United States with German precision engineering, the SAMS.15 incorporates Fritsch Sizing and Milling’s pharma-industry leading blade technology paired with Sample Automation’s innovative design to deliver the cannabis industry a superior flower milling machine.

The SAMS.15 comes equipped with 4 rotating sharpened blades and 3 stationary blades which results in 12 cuts per rotation allowing facilities to process 1-3lbs of material per minute. These blades can be moved and repositioned to achieve different sizes of material.

The SAMS.15 Cutting Mill is completely customizable, allowing you to determine exactly how your flower is processed down to speed, and exact particle size of your desired output. Speeds on the SAMS.15 range from 300RPM all the way up to 3,000RPM offering different sized operations the ability to process higher volumes and scale quickly.

At AGMS Solutions, we partner with like-minded vendors that think outside of the box. Sample Automation provides innovative equipment that is intuitive, well designed, easy to clean, and works. Just as important, the team is focused on the customer experience; timely feedback is always provided, and they can deliver solutions tailored to the customer requirements.

I thoroughly enjoy working with Andrew and Sample Automation in the development of novel processing solutions for cannabis. They consistently deliver functional, intelligent equipment that will be needed for cannabis 2.0 upgrades to 3.0 and beyond.

Your dream meets reality through Sample Automation. A true partner. Look no further for professional collaboration and development to meet your needs while solving industry challenges. Andrew and team listen, understand, formulate and bring to life the design and engineering that you could have only imagined. Integrate process flow and automation into your lab, pilot plant, or production process with Sample Automation hardware, instrumentation, and software control.

Set-Up

Applications

Agriculture and Hemp

Industrial Process Control

Pharmaceutical

Parameters

Input Formats

- 40mm(1.5″) Stainless inlet tube with 180mm(7″) plastic funnel

- 50mm(2″) Vacuum‘wand’ connected to a 75mm(3″) inlet hose barb

- 75mm(3″) Stainless inlet tube with 250mm(10″) stainless funnel

Dimensions

- SAMS 15Mill (46 x 66 x 124 cm/ 18 x 26 x 49 cm)

- SAMS 15 Frame (45 x 65 x 120 cm)

Controls

- LED mill speed setting

- Illuminated milling start/stop switch

- System power switch

- Emergency power disconnect button

Electricals

- 110V Single Phase 50/60Hz –15a

- 220V Double Phase 50/60Hz – 12a