Introducing the VHF 50.SS Automatic Feeding and Milling System

This complete automated solution is the most advanced upgrade available for the Pulverisette 19 Cutting Mill.

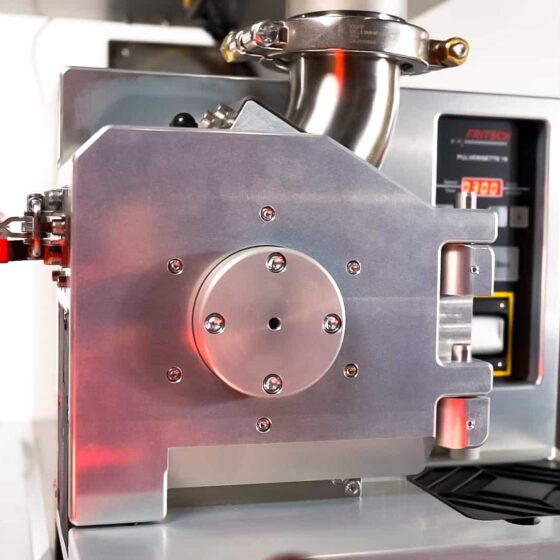

Introducing the VHF.50.19 Automatic Feeding and Milling System in partnership between Sample Automation and Fritsch Milling and Sizing. This complete automated solution is the most advanced upgrade available for the Pulverisette 19 Cutting Mill. The superior abilities of the P19 combined with the VHF automated feeder provide a reliable solution for larger facilities requiring an easily repeatable process that can be operated by multiple users. The automatic routine and the ability to request a specific amount of product milled from a stored hopper of material across a production cycle, provides facilities with consistent production reliability.

The all-Stainless-Steel hopper, agitator, and variable flight screw auger can keep material evenly level inside the hopper and stop product bridging. This provides a continuous feed of material to the sanitary exit cross attached directly to the input of the Puverisette 19 Cutting Chamber. The airpath starts at the top of the sanitary exit cross and is protected with a mesh gasket to allow airflow and viewability but no physical access. A silicone conical reducer provides the connection between feeder and cutting mill with an opaque view into the input of the milling chamber to verify the product flow from the hopper into the milling chamber. The negative pressure collection vessel then removes the biomass as soon as the particle size is achieved. This creates a more uniform particle size distribution of milled material from the specified sieve cassette chosen by the operator. That material is then collected, and the weight monitored by the VHF to stop the process once the desired amount is achieved. The automated controller of the VHF utilizes sensors to monitor the feeding path and internal material of the hopper. This indicates the internal volume of material to shut down once empty. It is also able to monitor for potential slowdowns within the Pulverisette 19 cutting chamber. The negative pressure collection system and weight scale are directly controlled by the VHF’s automated control box, allowing full control over all components of the system. A user is provided with a 5.7″ touch screen that can display with motion on screen the individual movements of the feeder’s agitator, auger, cutting mill, and vacuum state to give a user a full overview of the process.

The VHF is generally integrated with a direct collection system provided by Nilfisk as well as the cyclone exhaust system by Fritsch Milling and Sizing, but can also be integrated into custom solutions that a customer desires based on their individual production requirements.

At AGMS Solutions, we partner with like-minded vendors that think outside of the box. Sample Automation provides innovative equipment that is intuitive, well designed, easy to clean, and works. Just as important, the team is focused on the customer experience; timely feedback is always provided, and they can deliver solutions tailored to the customer requirements.

I thoroughly enjoy working with Andrew and Sample Automation in the development of novel processing solutions for cannabis. They consistently deliver functional, intelligent equipment that will be needed for cannabis 2.0 upgrades to 3.0 and beyond.

Your dream meets reality through Sample Automation. A true partner. Look no further for professional collaboration and development to meet your needs while solving industry challenges. Andrew and team listen, understand, formulate and bring to life the design and engineering that you could have only imagined. Integrate process flow and automation into your lab, pilot plant, or production process with Sample Automation hardware, instrumentation, and software control.

Set-Up

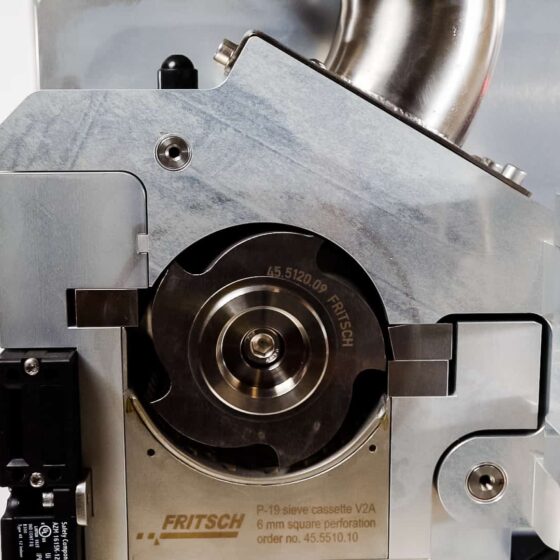

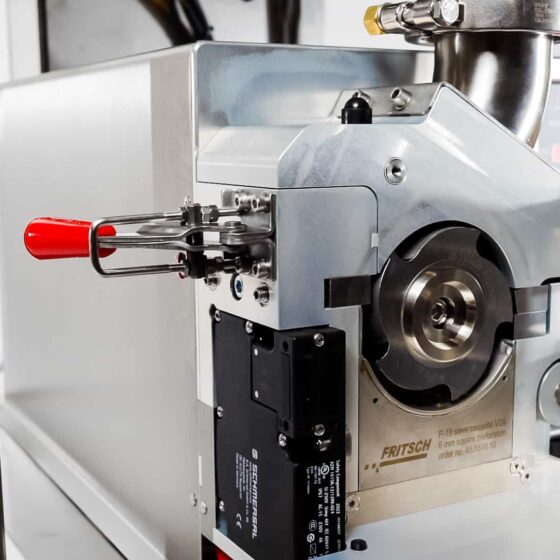

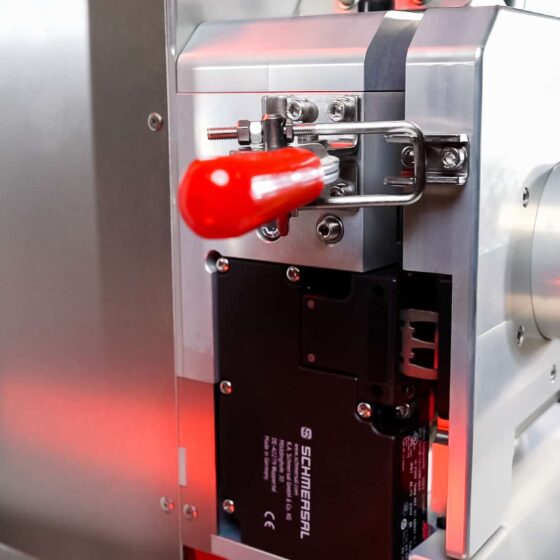

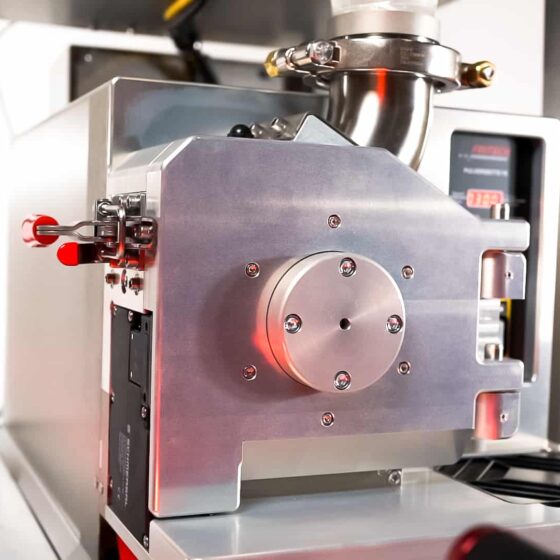

The VHF.50.19 Automated Volumetric Hopper Feeder system comprises of a 316 Stainless Steel 50L hopper with all 316 stainless steel contact components. The automated system comprises of an operator interface with a touch screen and mains controls of the system. The automated control is located in the rear enclosure with lower facing connections all easily identifiable for their component connections. The Pulverisette 19 is placed onto the cart underneath the Volumetric Hopper Feeder and will be directly powered via the control enclosure as with the collection system and the weight scale. Be sure all the components are attached and working correctly when following the initial installation instructions. Check the connection between the VHF and the P19 making sure all clamps are tightened sealing the exit path of the feeder to the input of the P19 according to the installation and assembly instructions.

Product will be filled into the hopper from the top by lifting the lid. At any point in time, if the hopper lid is open both the internal hopper agitator and auger will not function or move until the lid and interlock are securely closed. The user would initially fill product into the hopper before operating the system. After selecting a pre-set recipe from the stored memory. The control recipe will individually start the overall system’s components. This automated routine specifically aims to stop user error and increase efficiency. A user simply needs to press the start/stop button on the touch screen to initiate the process and once the desired amount of material is collected, the system will shut down and indicate to a user that the process is complete.

The VHF is integrated with a feeding path laser detection sensor that is constantly checking for product flow feeding to the cutting mill. Once the sensor stops detecting product for a specified period of time the system will stop and indicate to the user that more product needs to be provided to the VHF. Once more product has been added, the milling process can be continued. It will also work in a reverse function as when product is detected for a specific period of time, the system will shut down to stop over feeding of material into the chamber. The VHF also has a built-in pause function that will stop the milling process after a pre-determined period of time; stopping the process for a cool down period, if required. These parameters and pre-set product recipes are protected by a password to allow an administrator to setup the desired values without worry of changes by unauthorized operators. There is also a manual operation page for a user to individually control the operation of the system. One unique feature of the VHF system is that it includes the ability to operate the Pulverisette in the SAMS.19 mode, also providing the same automation with manual feeding if required.

The VHF.50.19 can be disassembled with a single wrench and easily reassembled with minimal downtime. The hoppers internal screw feeder can be easily removed by untightening the clamp holding at the front of the sanitary exit cross. Removing this plate with bearing will provide access to the screw auger which can be removed horizontally from the hopper and reassembled the same way being sure to set the screw auger correctly within the keyed shaft. The internal agitator can be wiped down in place with the lid open but can additionally be removed if required. The Pulverisette 19 can be disconnected from the silicone conical reducer by removing the double bolt clamp and following the cleaning procedure provided from Fritsch for the Pulverisette. Once all components are cleaned the system can easily be wiped down in place.

Applications

Agriculture and Hemp

Industrial Process Control

Pharmaceutical

Parameters

Features

- Stainless Steel Hopper Assembly

- Stainless Steel Agitator with Variable Speed

- Stainless Steel Flight Auger with Variable Speed

- Smooth Finished Welds

- Direct P19 Attachment

- Sanitary Silicone Reducer Attachment

- Food Grade 304 & 316 Stainless Steel Frame

Electricals

- 110V Single Phase 50/60Hz –1725 watt, 8Nm

- 220V Double Phase 50/60Hz – 2350 watt, 10Nm

- 400V Three Phase 50/60Hz – 5000 watt, 30Nm

- Nema 34 – 12Nm20A 24VDC Stepper Motor

Controls

- 5.7″ Touch Screen HMI

- Emergency Stop and Isolation Switch

- Automated Auxiliary Controls

- SOP Recipe Speed and Setting Controls

- Password Setting Controls

- Feeder Exit Port Laser Sensor

- Collection Container Point Sensor

Dimensions

- VHF.50.19: without Cyclone (102cmL x 60cmWx 178cmH)

- Weight: 175Kg