Introducing the CRM 21.01 Crown Smart Vessel by Sample Automation

Standardize, automate and scale the production of high-quality THC-A Diamonds, High-Terpene Sauce and Rosin.

Introducing the Crown Smart Vessel by Sample Automation. The Crown Smart Vessel allows manufacturing facilities to standardize, automate and scale the production of high-quality THC-A Diamonds, High-Terpene Sauce and Rosin. Traditionally, manufacturing processes have been slow and unpredictable, consuming valuable laboratory resources, oven space and labour. The amount and quality of the outputs have also varied widely and remain difficult to scale effectively or record for consistency and reproducibility.

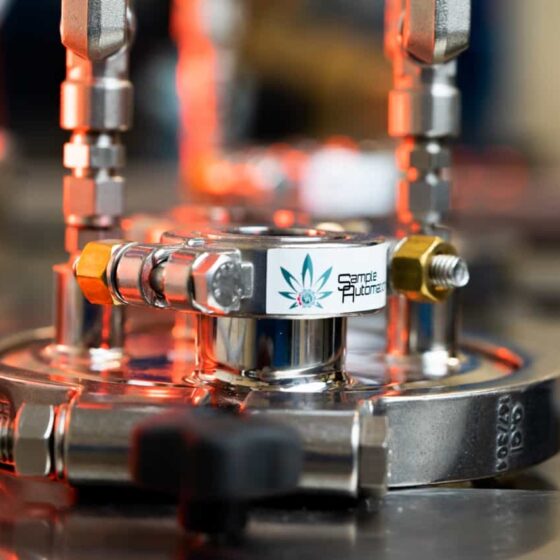

This all-in-one PC and microprocessor-based system allows operators to monitor, track and control each step throughout the reaction process, offering real-time data insights into production capabilities. This smart vessel comes equipped with pressure, temperature, and ventilation controls which accelerate the timescale of the separation process to start seeing results quicker and more repeatable.

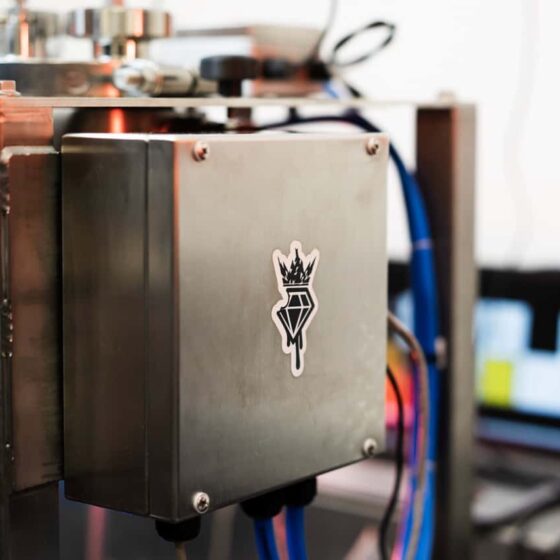

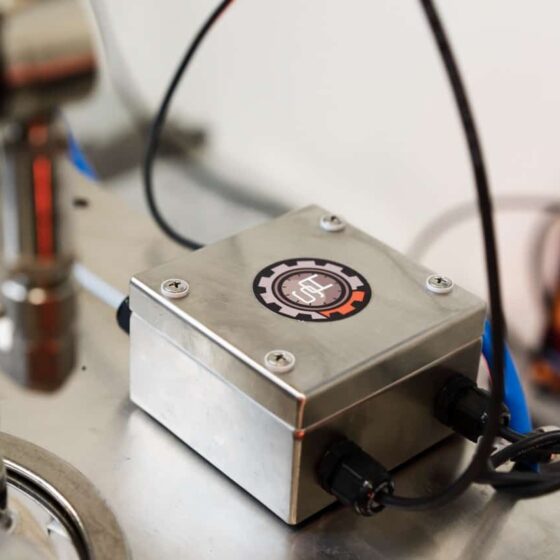

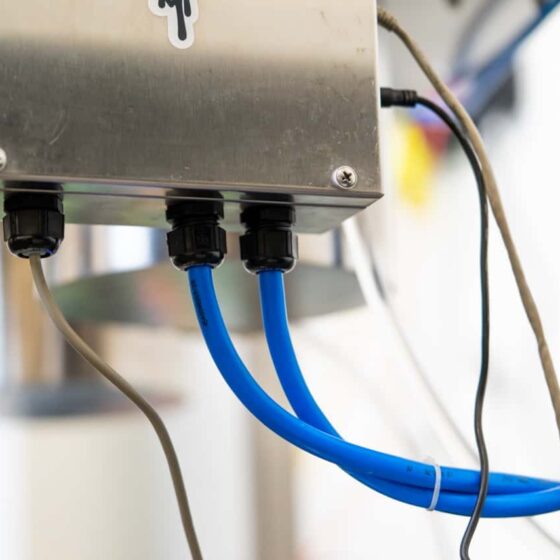

The Crown Miner uses a custom designed microprocessor PCB with embedded firmware which serves as the unit’s control brain always working autonomously from the dedicated PC software. The software acts as an interface and display for the miner’s operation and data logging. If disconnection from the software was to occur, the controllers will continue to operate and track data until reconnected to the pc software. This firmware is specifically designed with intrinsically safe temperature and pressure sensors, auxiliary external interface protocol connections, and network connection integration, while remaining small and compact. This master controller, though small, is powerful and serves as the system’s “brain” pulling together components both integrated and auxiliary. In addition to allowing users to control the pressure, temperature, and ventilation inside of the vessel. The control unit is constantly monitoring, tracking, and recording this data with additional auxiliary and devices control for further process optimization and reliable reproduction. All data is recorded in a raw format for easy integration to existing data management software for an overall production to be tracked. Allowing operators and technicians real-time feedback into their processes enables them to capture specific textures and products recording the formulas that can be repeated in the future. The Crown Smart Vessel enables manufacturing companies to stay compliant, produce consistent results, and increase output while reducing operational requirement of personnel within the facility.

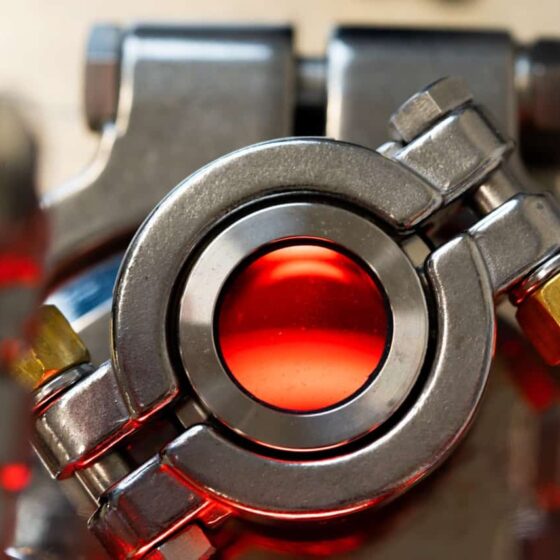

The system is comprised of 4 main components: The Crown Trident Caps (equipped with both analogue and digital tridents), jacketed vessel, controller, and computer. The Crown Smart Vessel can be fully customized with 2 vessels per controller and custom stand. Each vessel or pair of vessels can be attached to a circulator for temperature control. Additionally, they can be upgraded to refrigerated circulators and cold traps. This allows manufacturing teams to operate the vessel externally from the hazardous extraction area inside the production facility. A software licence is provided with every computer with the ability to operate up to 4 controllers, 8 vessels and 8 water circulators linking all auxiliary components. All Trident Caps are assembled ATEX C1D1 components and if required are supplied with the additional electronics to place the vessels and sensors internal to the hazardous area if required.

At AGMS Solutions, we partner with like-minded vendors that think outside of the box. Sample Automation provides innovative equipment that is intuitive, well designed, easy to clean, and works. Just as important, the team is focused on the customer experience; timely feedback is always provided, and they can deliver solutions tailored to the customer requirements.

I thoroughly enjoy working with Andrew and Sample Automation in the development of novel processing solutions for cannabis. They consistently deliver functional, intelligent equipment that will be needed for cannabis 2.0 upgrades to 3.0 and beyond.

Your dream meets reality through Sample Automation. A true partner. Look no further for professional collaboration and development to meet your needs while solving industry challenges. Andrew and team listen, understand, formulate and bring to life the design and engineering that you could have only imagined. Integrate process flow and automation into your lab, pilot plant, or production process with Sample Automation hardware, instrumentation, and software control.

Set-Up

Rosin Decarboxylation Process:

The Crown Smart Vessel is one of its kind because of its versatility. As the manufacturing industry continues to evolve, we realize the huge opportunity to support all types of extraction including solventless. Though we originally sought out to improve the hydrocarbon extraction process and experience it was quickly determined our Smart vessel was even smarter than we could have imagined. The system was also capable of rosin decarboxylation. This was possible from smart vessels ability to track and record the temperature and pressure parameters utilizing the Ideal Gas Law to calculate the correct routine to increase speed and accurately determine and repeat the process for a reliable production. This data is utilized in combination with the software to predetermine a routine that allows for the process to be self-verifying at the end of the production process. A typical process would involve using fresh or stored rosin material being filled into the vessel and sealed closed. Once sealed and closed the software can be started to control the circulators or heating pads to increase the temperature of the vessel starting the decarboxylation process. The combination of temperature, pressure and ventilation will allow for an accurate process in a controlled repeatable manner. The vessels can then be used as storage containers by utilizing the back gassing features to create an inert environment to stop oxidization for a longer shelf life and between production, verification, and packaging for distribution. The unique process truly takes advantage of the Crown Smart Vessel. The process was formulated by Corey Crosser with 20 years of industry experience, he was able to work with Sample Automation to add this feature to the Crown Smart Vessels add on features.

Diamond Crashing & High Terpene Sauce Separation Process:

A typical Production run of live resin diamonds using a butane hydrocarbon extraction method consists of; a starting batch of material at cold temperatures for THCA extraction to reduce the chances of dilutants to the mother liquors THCA to solvent ratio which is the main factor to the chemical process of creating diamonds. Once the extractor has started the agitation of the collection separation column and the mother liquor is collecting in the lower vessel. By intentionally removing the collection vessel from the extractor with a higher level of solvent is critical to the process. The extractor will then pour that solvent/liquor solution into the miner vessel, cap the vessel with the Crown Miner Cap and check for seal leaks from the vessel with a handheld hydrocarbon monitor. The vessel can then be approved to be removed from the hazardous area and immediately attached to the miner controller and ventilation pipework. Once the vessel is connected to the controller the user will move their operation over to the PC and Device Manager Software program. Within the program a user will already be connected to the controller via the device selector area of the software and then engage the vessel they have just connected to the software. A user will then be presented with a graph and real-time readings of the parameters of the sensors and vessel auxiliary devices. The individual vessel can have individual setting for data logging, temperature control and ventilation routine. These settings are expandable and incorporate a ramping function to have a temperature routine running for the vessel. Custom routines outside of the standard scope of the software can also be customized for the individual user or facility at additional cost. The controller and software use ethernet or USB as forms of communications to the PC. It can be integrated into an existing network of a facility allowing the pc to be located remotely away from personnel to only be touched once the vessel is ready to be harvested by a manager. The controller will continue to operate with all the settings and parameters set by the software if the connection was ever lost. All the data can be set to log in a specific location on a server or network location. In addition, it has features like roll reports and template reports that will auto generate into printable documents for compliance and trackability within a facility or integration into an existing tracing or metrics program. The Crown miner system can be customized in both standard and more sophisticated arrangements and are great to integrate into existing productions. The vessels can be replaced with existing vessels from the extractor manufacturers as the collection vessel on the extractor can act as the same vessel as the miner vessel allowing for an easy and streamlined process. They can also be upgraded over time by replacing heated circulators with refrigerated circulators to increase the operational temperature range for the vessel. Additionally, the controllers can connect to up 2 vessels with the software license able to connect to 4 controllers making a total of 8 vessels per software license. Systems can be designed for these larger arrangements on individual customer or facility bases. The Crown Miner Smart Vessel is an intelligent product that is designed to increase production and safety capabilities for THC-A production as diamonds or sugars as well as a group of other products in the cannabis industry. The vessel is being used for more and more processes within laboratories and will allow a user to gain a better understanding of some of the post processing variables that effect the repeatable production for a facility.

Applications

Agriculture and Hemp

Industrial Process Control

Pharmaceutical

Parameters

Software Features

- Multi parameter trend screen with lines for multi day presentation

- Windows based

- Operate up to 8 vessels with one license

- User settable parameters: Discharge, Temperature, Pressure and Water Bath

- Data logging to neutral .xls files and Roll Reporting for end of process consolidation

Miner Features

- Continuous monitoring and automatic adjustment of tank pressure and temperature

- ASME approved Jacketed Tanks

- Dual windows for viewability of crystal growth

- Quick disconnect of vessel for liquor input and removal of crystals

- Manual and Automatic PRV valves

Dimensions

- 71cm x 60cm x 41cm (L x H x D)